Introduction:

Scaffolds are temporary framework systems used to support workers and materials in the construction or repair of buildings and other large structures while they work at a height (≥ 1500 mm). It is usually a modular system of metal pipes (usually mild steel and aluminum alloy tubes), although it can be made out of other materials like wood. The purpose of a working scaffold is to provide a safe place of work with safe access suitable for the work being done. A suitable scaffold must be designed to support four (4) times the weight of the workers and materials resting on it. A scaffold can be stationary (with a fixed stand) or mobile (with a rolling stand for movement). For an ongoing project, all scaffolds must be inspected every morning before new work. Scaffolds that are safe to use will be tagged with green scafftag while those not safe to use will be tagged with red scafftag

Types of Scaffolds

There are many types of scaffolds existing as outlined below:

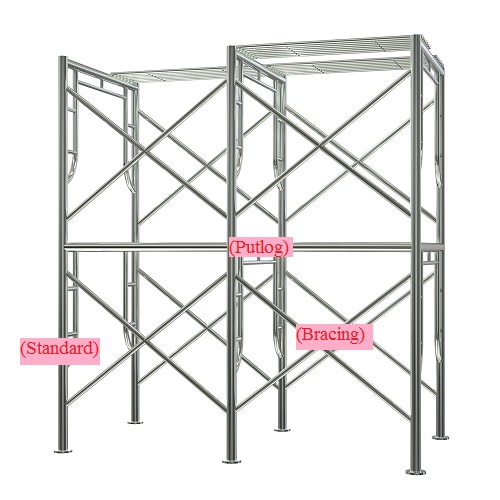

1. Putlog or Independent Scaffold: This consists of a single row of standards (vertical members) that are set approximately 1300 mm from the outside wall of a building which partly helps to support the scaffold (see image below).

2. Independent Scaffold: This consists of a double row of standards, which are set about 1050 mm apart and do not depend on buildings or walls for support (see image below).

3. Cantilever or Trussed Scaffold (see image below)

4. Suspended Scaffold

5. Chimney Scaffold

6. Roofing Scaffold for roofing work generally

7. Birdcage Scaffold: interior scaffold for works below ceiling height

8. Slung Scaffold: usually hung from the underside of roofs, where it is impracticable to erect a scaffold from the ground.

9. Mobile Scaffold: where the height should not be more than 3 times the width of the base (see image below).

10. Prefabricated Scaffold: where the units are fabricated into usually ‘H’ shaped interlocking frames.

Rules when Setting up Scaffold

Foundation

Select a secure foundation on which to build and set your scaffold – obtain mud sills or base plates to attach the scaffold to make the footing more stable. One of the main concerns here is to have the scaffold on level ground and secure ground. If you are on unlevel ground, you dig down to make the ground level in all corners. Also, use adjusting screws on the scaffolding to level the structure. If the surface is on a drastic slope, obtain leg extensions.

Spacing of Scaffolds

The spacing of standards will depend on the use or weight for which the scaffold is intended:

For Masons – 1200 to 1800 mm apart is recommended.

For Bricklayers – 1800 to 2400 mm is recommended.

If standards are 2400 m apart, the load should not exceed the approximate weight of 2 men, 50 kg of mortar, and 80 bricks/blocks. If standards are 1800 mm, the load can be increased but should not exceed approximately 2 men, 50 kg of mortar, and 140 bricks/blocks.

Safety Note: No more than 2 men should be on any one span at any time when loaded as above, and no other materials should be wheeled or carried across such spans.

Intermediate Putlogs

For putlogs scaffolds, intermediate putlogs will be required according to the thickness and length of the scaffold board (in order to support them) as follows:

| Thickness of board | Maximum spacing of putlogs |

| 30 mm | 925 mm |

| 38 mm | 1500 mm |

| 50 mm | 2650 mm |

The boards must be supported at a distance of not more than 4 times their thickness from their ends in order to prevent the boards from tipping.

Note: bracing or stiffening of scaffolds must always be provided where pulley blocks or lifting appliances are fitted to be a scaffold or when placing heavy loads upon a scaffold.

Dismantling Scaffolds

1. Tubes or fittings should never be dropped to the ground, all scaffolding should be lowered carefully and stacked flat.

2. Collect fittings in sacks or bags

3. When not in use, tubes should be cleaned and stacked.

4. After fittings have been checked, they should be soaked in light oil and if possible stored in drums.

Minimum Width of Working Platform for Scaffolds

(See image below)

Note:

1. Working platforms must extend 600 mm beyond the end of a wall.

2. Scaffold boards should be not less than 200 mm wide; extend not more than 4 times the board thickness beyond the support; be fitted with beveled pieces (to make it rigid) where necessary, and rest on 3 supports or putlogs.

3. Guard rails must be provided if the platform is 1950 mm or more in height; must be 900 mm above the platform, and must be not more than 675 mm above the toe board.

4. Toe boards must accompany the guard rail and must be 200 mm high or more.

5. Ladders must extend 1050 mm above the platform and must be on a firm footing. They must be secured or tied to prevent slipping. The defective ladder must not be used.